Mig Welding Aluminum Vertical Down

03 10 2008 02 25 pm hey guys its once again been a long time and we are starting solid wire.

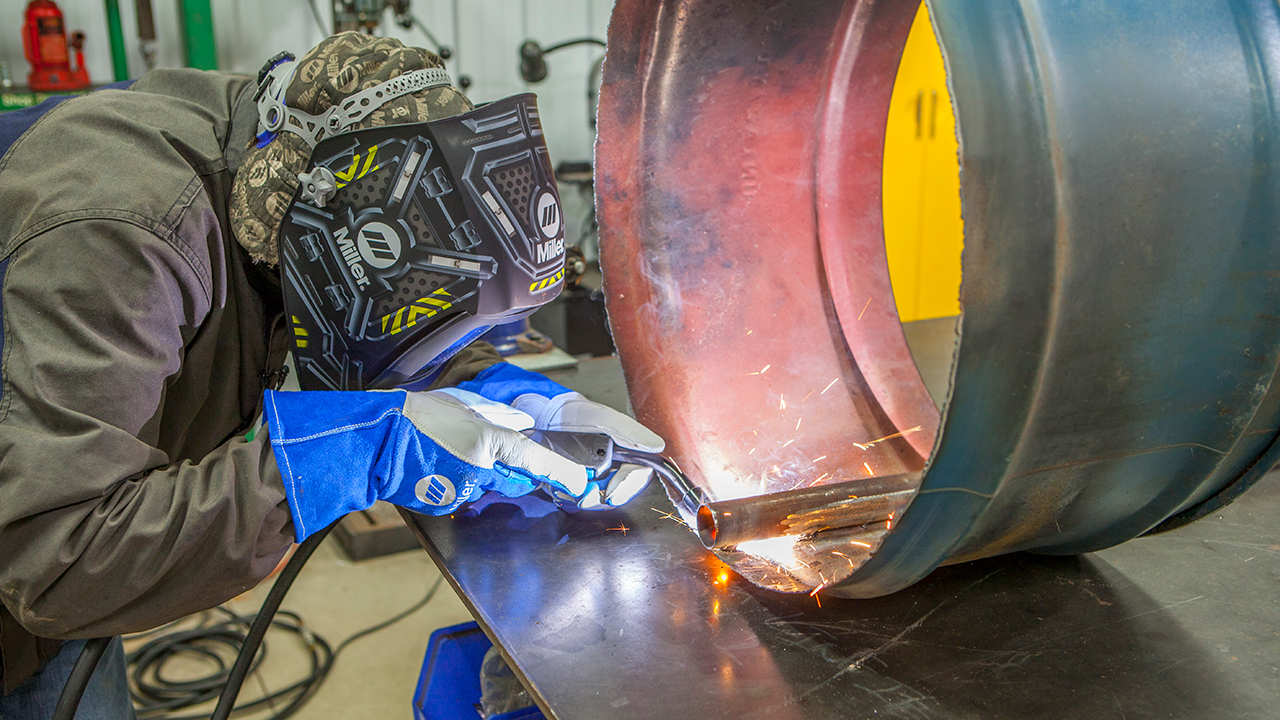

Mig welding aluminum vertical down. A vertical down welding starts from the top of the joint going down to the bottom. I did an experiment about a year ago on a mig welding technique that i use for vertical uphill mig welding. Professionals or skilled welder opt for the vertical up movement. Flat and horizontal welds are fairly easy but vertical uphill welds contend.

Vertical down mig welding most people who learn to vertical weld on their own use this technique. Aluminum vertical up tips 11 03 2005 01 36 pm i have two jobs i am working 13 1 2 hr days. When welding vertically many welders prefer the vertical down movement as here gravity aids the process. This avoids excessive i d.

After my ojt placement i was mig welding my verticals down but yet my teachers are saying that doing it. Weld the balance of the joint out with ether gmaw spray or short arc or smaw. Run root pass downhill short arc. Mig vertical up or down.

So i put up a short video on youtube just to see what would happen and if viewers. The slag remains concentrated in the middle resulting in weaker material penetration on the sides. This video shows you how to properly execute a fillet weld in the 3f vertical position with the weld progression going down using the gas metal arc welding gmaw mig process. I wire feed at my first job 10 years.

I used the hobart recommended settings for 024 6mm wire. 2nd job wire feed aluminum and tig. This welding position is a lot easier and faster with the puddle being easer to control while providing a clean and nice weld. The upside down v is one of the most effective technique for vertical mig welding of lap and tee fillet welds.

Click here to see part 2 of downhill mig mig welding 1 8 3 2mm cold rolled the first joints i welded in this video were cold rolled finish and roughly 1 8 3 2mm thick. I have seen and done gmaw welding in vertical joints as follows. Thanks for watching. However for thicker metals this is not a good idea.

Penetration and burn through. Bevel the root with no land when welding the root use a slight weave to tie in both sides of the bevels.