Pallet Stretch Wrapping Machine Risk Assessment

We partner with industry leading manufacturers to meet standard and unique packaging requirements.

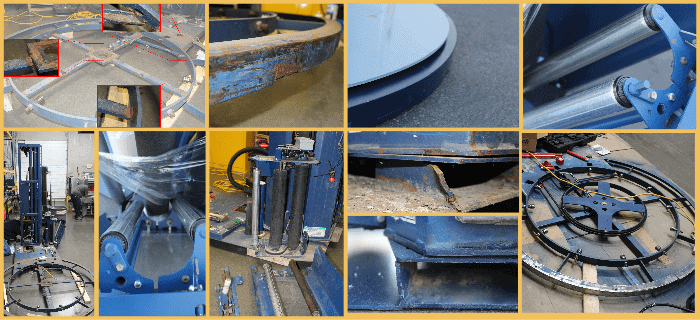

Pallet stretch wrapping machine risk assessment. Load does not overhang the rotary table. Moving parts can trap fingers hands arms etc causing crush injuries. Clean machine once a day. It is a combination lift table with a motorised turntable and combined with our easy wrapper semi automatic film wrapper mast.

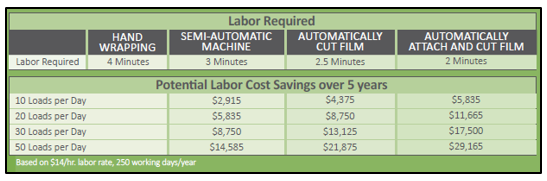

Start with a machine guarding risk assessment. Turn off the stretch wrap machine when finished. As few as 10 pallets per day wrapping requirements can justify a pallet wrapper. Manual semi automatic stretch wrapper or high speed automatic stretch wrapper.

This is ideal where space is a premium. These are general safety guidelines to be used for a variety of stretch wrap machines. Stretch wrappers are a must for any business wrapping more than 10 15 pallets a day. Example risk assessment for a warehouse.

A worker secures the film to the pallet and then walks the film around the load. Dec 1 2016 simple stretch wrap machines are nearly as ubiquitous to loading dock areas as dock pulling and moving stretch wrap around a pallet is now commonly automated. Semi automatic stretch wrap machines require an operator to place the pallet loads on the stretch wrapper and initiate the stretch wrapping cycle. We sell and service a wide variety of tapers including cousins fox robopac and eagle.

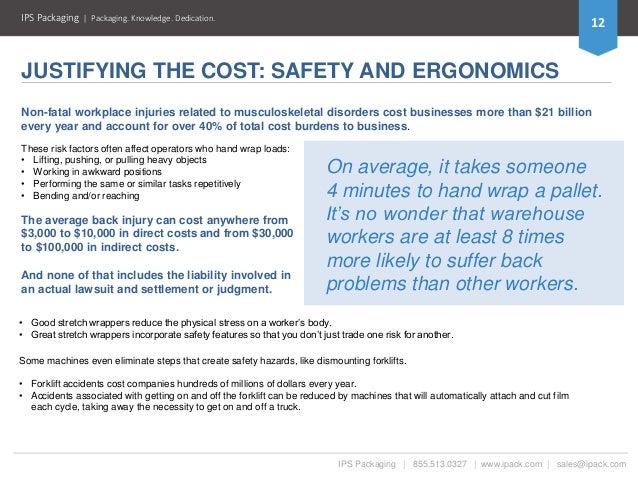

Using a stretch wrapper machine can reduce your labor cost and provide an immediate return on your investment. 3 ways to apply stretch wrap. Keep machine and surrounding area clean clear and free of debris. Staff can also be cut by sharp edges or scalded by hot parts.

If manual wrapping must be performed use rolls that weigh as little as possible to minimize the lifting hazard. Hand wrapping as the name implies relies on people to manually stretch wrap a load. Stack and wrap combination allows semi automatic palletising and stretch wrapping at the same location. Stretch wrap machine instructions show it meets the staff using the machine.

Find your pallet wrapper at rapid packaging. The whole body may also get trapped between moving pallet load and fixed structure. Use caution when stepping on or walking off the turntable. Distance between the rotary table and fixed points like the film reel assembly pillars or walls is 500mm or more.

Only step on the turntable when power is off. Clause 5 3 2 1 1 establishes the principle that risk from the rotating pallet load is acceptably low provided that the. The stretch wrap machine then applies the stretch film and wraps the pallet load to meet your requirements. There are three ways to apply stretch wrap to a pallet of products.