Lexan Vacuum Forming

The piece is going on a railroad sign prop.

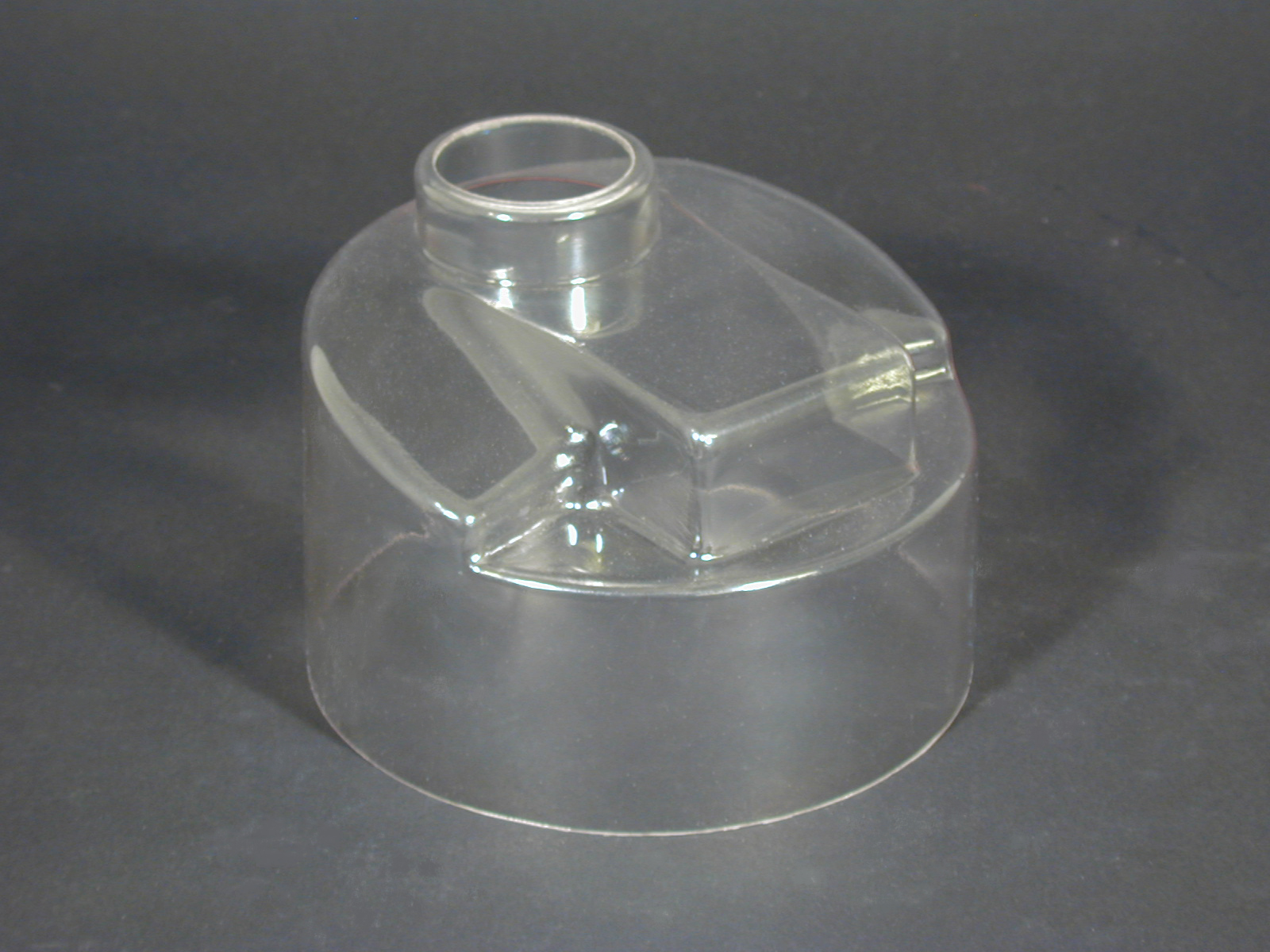

Lexan vacuum forming. Depending on the thickness it may be possible to vacuum form your shape the best company to perform this would be a prototype house or maybee a local university with a lab unit. It is virtually unbreakable. It s the sun shield for the lights. Forming temperature i believe is about 375f.

Get it as soon as thu oct 8. It is similar to glass but is much stronger and lighter. Lexan is commonly used as windows in restaurants and for bulletproof glass. Since lexan sheet cools rapidly it is essential that final control and heating is carried out on the forming machine itself.

At this temperature the material has good extensibility and will vacuum thermoform to detail that is adequate for most applications. Bend mold than plexiglass. For vex robots hobby diy industrial crafts. Lexan is a type of polycarbonate plastic.

3 16 is going to need about 18 hours at 250f. Using forced air heat to bend 1 16 poly into a half circle. The most suitable material aould be polycarbonate however forming it could be quite hard as it must be heated to about 250 to soften it. Normal sheet temperatures are in the range of 170 c 225 c for mechanical and vacuum forming.

If you omit this step it will make a good shower door as it will be nothing but small bubbles from steam trying to escape. Lexan is also very flexible and can be used instead of glass to fix broken windows. Optimum forming conditions depend upon part design draw ratio sheet thickness and the forming technique employed. Normal sheet temperatures are in the process window of 170 c 225 c for vacuum forming.

Check here for supplemental information parts lists. Free shipping on your first order shipped by amazon. 4 6 out of 5 stars 766. Lexan requires a drying time in the oven at 250f for a time period of 1 hour for each 0 010 material thickness.