Lamination Test Of Steel Plates

Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure.

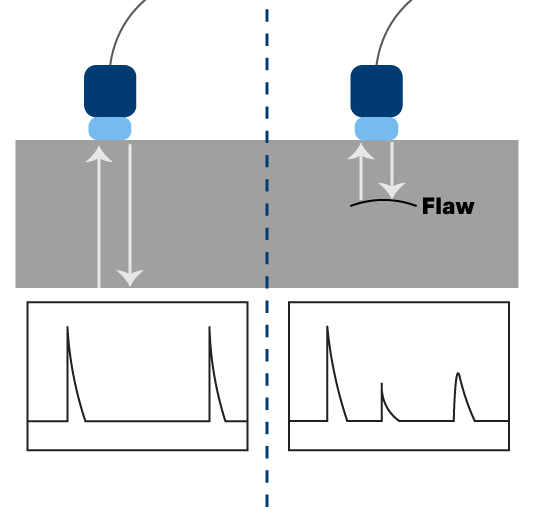

Lamination test of steel plates. With or without matte borders. Simple theoretical considerations predict that the presence and location of such laminations can. Describes the ultrasound testing of steel plates for pressure tanks. Utman ultrasonic weld testing and training ultrasonic inspection simulation http www utsim co uk.

Available in 0 8 thickness. It was developed to assure delivery of steel plates free of gross internal discontinuities such as pipe ruptures or laminations and is to be used whenever the inquiry. 12 5 mm and over in thickness. Rz 0 40 0 92.

The lamination is located less than an inch from the hole that accepts the shackle. Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels. The carbon steel blister in photograph would be an exception to that comment. Thus the need has arisen for some effective method and means for detecting such flaws in structural steel material.

Recommended in environments where a high degree of blocking occurs. Because inclusions and laminations are not always found throughout an entire bar plate or other form we should attempt to work through the issue. Hardness bhn 179 hrc 30. Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure.

All standard steel plates contain these. Lamination plate 2 dull mirror lamination plates type d3. We regularly test entire plates 1 1 2 and greater prior to and after completion of welding to insure there has not been any delamination or through thickness shrinkage. Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels.

1 1 this specification 2 covers the procedure and acceptance standards for straight beam pulse echo ultrasonic examination of rolled fully killed carbon and alloy steel plates 1 2 in. Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure. Laminations in the plating and other members of fabricated steel structures cause weaknesses and failures in present welded junctions that did not occur in the case of riveted joints. Describes the ultrasound test method used for testing carbon and low alloyed sheet steel and universal profiles and defines a quality classification.

300 series stainless steel.