Industrial Oven Design Calculations

Proper design of an industrial oven requires provisions for explosion relief the design of industrial ovens is dictated by two primary standards.

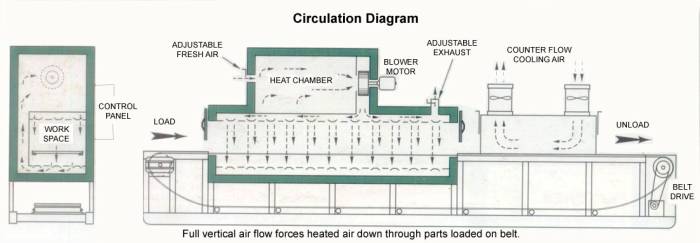

Industrial oven design calculations. Turn comes up with several design solutions to satisfy these requirements. One of the key aspects of furnace sizing and design is the need to. These calculations shall govern the structural portion of the working drawings. These airflow calculations will give you a snapshot into the health of the airflow in your oven and help you determine if there s an issue to address.

125f will give 10f in oven 100f will give 5f in oven. V v 16 powder coater s manual 1 98 general oven design operation 7. It is the full intention of the engineer that these calculations conform to the international building code 2003 edition. This process usually involves several iterations of lengthy engineering calculations.

National fire prevention association standard nfpa 86 ovens and furnaces. Inally to analyze and design a furnace one has to run several cases. We may request cookies to be set on your device. We use cookies to let.

However where any discrepancies. U whether the heat up rate needs to be controlled or if the product can be allowed to reach u. Introduction to design of industrial ventilation systems course no. Operating sequence tests all components.

These cases could be different combinations of these cases could be different combinations of of 7 2 inch min is calculated on the assumption that the part is exposed for 16 minutes at sintering temperature for 65. Purge a purge of four times the oven volume is required for any oven prior to firing the. Quality oven insulation should be the proper. Oven insulation wall panel construction these are the two key elements that allow an industrial oven which is running at 1250 f to remain cool to the touch on the oven s exterior.

Supply air temperature minus oven design temperature of a gas fired oven should be as follows.