Industrial Oven Calibration Procedure

1 0 scope and application.

Industrial oven calibration procedure. Calibration procedure is limited to ovens operating to a maximum temperature of 300 c. 5 1 2 switch on the precision oven. Temperatures in the oven can exceed 400 f. Close tightly the oven door.

5 1 3 adjust the required temperature by adjusting temperature knob soft key. Ifstringent calibration tolerances are. Whether you use small ovens batch ovens walk in ovens or conveyor ovens transcat s oven calibration services will make sure they operate correctly and consistently. Then it s a matter of adjusting the digital pads or knobs to reflect the proper temperature of the oven.

It s best to first check how far off is the oven temperature using an oven thermometer. The oven is designed to replace 20 of the air with fresh air in order to maintain low levels of co but caution should be used in case of an unsafe co level inside of oven. 1 2 2 house keeping the inside of the oven top of the oven and sides of the oven. Calibrating an oven requires only a few simple steps.

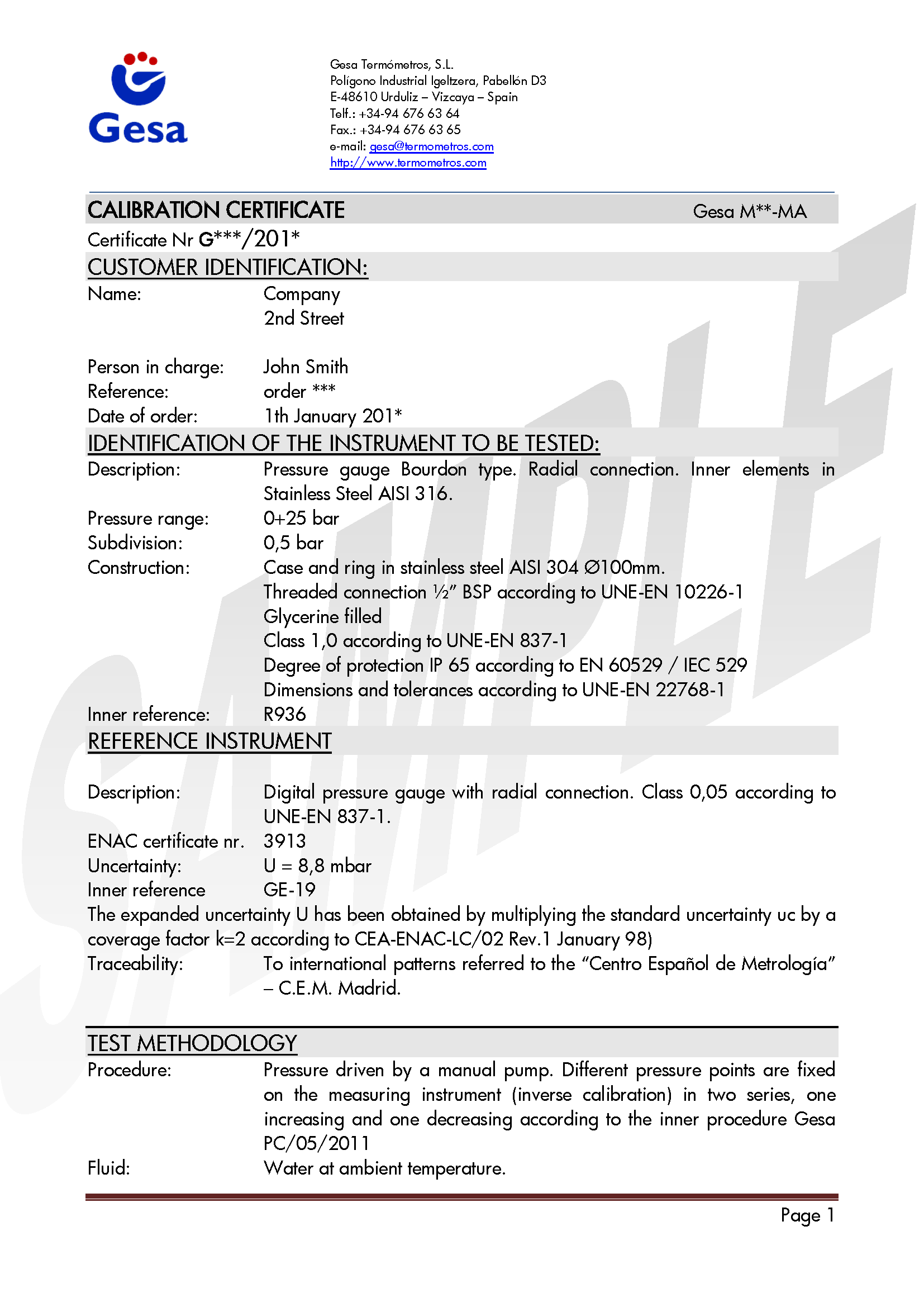

First we measure the temperature in your oven using a digital thermometer to see whether or not the actual. 5 0 procedure 5 1 operation 5 1 1 ensure that temperature indicator is within due date of calibration. Wisconsin oven offers complete calibration services for temperature controls and recording instruments which include nist calibration certificates and iso17025 accreditations from a2la for all makes of industrial furnaces ovens environmental test chambers walk in chambers and a variety of other lab equipment. February 13 2009 page 2 of 13.

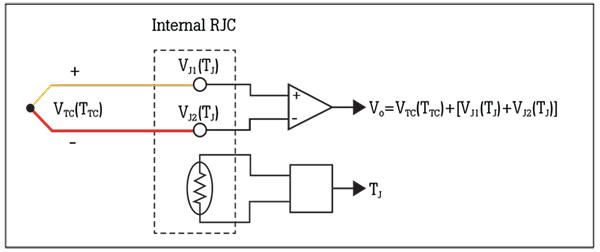

We offer installation operation and product qualification packages for all makes of environmental test chambers dry heat sterilizers walk in chambers and a variety of other lab equipment. Transporting product in and out of the oven. Ovens operating at higher temperatures require special handling and there fore shouldbeperiodically checked by themanufacturer. This is a step by step procedure for calibrating the sample oven thermocouple of a carbon.

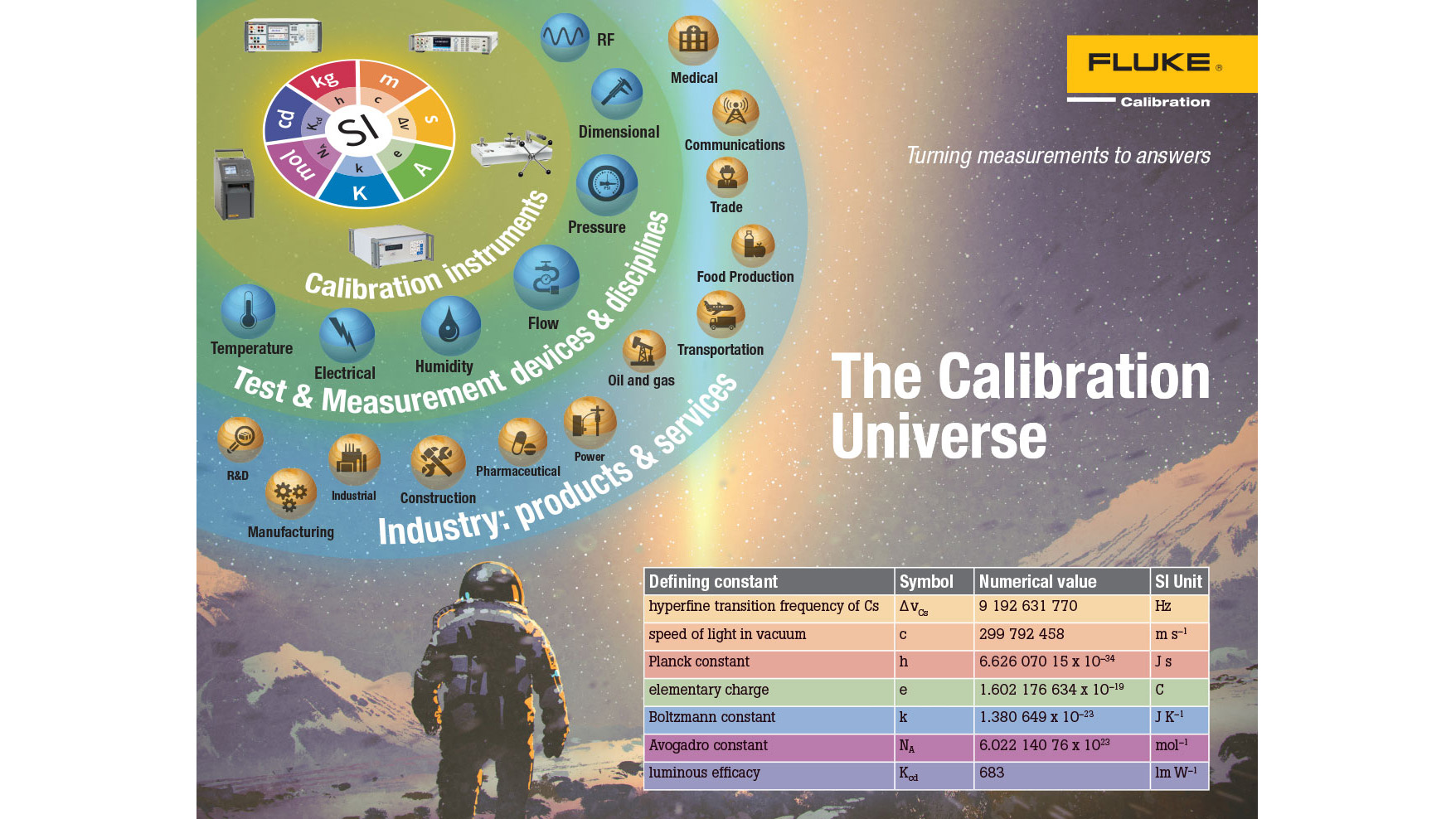

Some ovens takes an hour to reach the test point before stabilization. These can be bought in most grocery stores. Industrial oven calibration is a necessity for manufacturers heat treaters and other businesses that rely on temperature accuracy for proper performance of industrial furnaces and ovens during production this service is imperative for ensuring accurate and consistent processes and energy efficiency. Oven calibration temperature uniformity survey system accuracy test and more.

Thermal product solutions tps rounds out our total service packages with the ability to provide complete calibration service to include nist calibration certificates and iso17025 accreditations from a2la. The basic procedure to calibrate electric oven is to compare the generated temperature of the oven through the set value in the dial knob to the reading of the reference standard which is a digital thermometer with a thermocouple wire as the sensors. 1 2 this procedure is to be used for periodic checks oflaboratory ovens.